Often when repairing our own vehicle, we find, that some thread has been damaged and the connection of two elements is impermanent or even impossible. This is the result of the screw being screwed incorrectly into the socket, material defects or fatigue, There are several repair methods and they depend both on the type of damage and the workshop equipment. No problem, if we can drill the hole and thread it to a larger standard size.

Often when repairing our own vehicle, we find, that some thread has been damaged and the connection of two elements is impermanent or even impossible. This is the result of the screw being screwed incorrectly into the socket, material defects or fatigue, There are several repair methods and they depend both on the type of damage and the workshop equipment. No problem, if we can drill the hole and thread it to a larger standard size.

One of the most serious damage in internal combustion engines is the breaking of the spark plug socket threads in the head. Converting the most popular M14 spark plug thread to an M18 thread is usually impossible, because in modern heads, and especially in the heads of four-stroke engines, there is no room for this. In addition, we will encounter difficulties in obtaining a candle that is suitable for heat value. In this situation, workshops offer us to remove the head and insert a reduction. This method is quite commonly used, however, it has many disadvantages:

– materiał użyty do redukcji jest najczęściej inny od materiału głowicy, what causes, that with different thermal expansion after some time the reduction will twist with the candle or the connection will become leaky, while pinning or crimping the reduction from the inside does not always produce the desired results

– kołnierz redukcji powoduje, that the plug is retracted with respect to the combustion chamber and the operating conditions of the cylinder change

– wysoki koszt naprawy tzn. disassembly of the head, possible valve adjustment, the need to tighten the head after some time and the price of the head gasket.

From my experience it follows, that the ideal solution is to use a special Heli-Coil thread insert; repair method known in Poland, unfortunately, due to the necessity to purchase tooling and inserts for convertible currencies, it is not widely used, however, having a repair kit by workshops and service stations for frequent repairs of this type is certainly profitable.

What is a Heli-Coil Thread Insert?

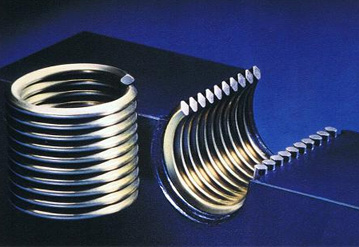

Austenitic chromium-nickel steel wire with a slant cross section is coiled into a springy helix and forms a concentric internal and external thread. Before assembly, the outer diameter of the insert is by a strictly calculated value greater than the outer diameter of the thread in the hole, in which it is to be screwed. The screw-in insert is under tension and therefore self-locking, creating a calibrated internal thread with the original nominal diameter. Due to its characteristic properties, such a thread turns out to be even better than a cut thread.

The repair consists in cutting a special tap with a new "pilot" (a little bigger) thread in the candle socket in the head, inserting the Heli-Coil insert into the socket in the head using a device and breaking the tip (zabreraka) inserts .

The advantages of the thread repaired with this method are unquestionable:

– zwiększona wytrzymałość gwintu wynikająca z dobrego przylegania powierzchni

– większa jest odporność na ścieranie, thanks to the use of 18CrNi8 steel, and the high surface smoothness reduces the thread friction

– wkładka – thanks to its structure – ensures perfect tightness, and its tension in the socket prevents unscrewing the insert with the candle

– do naprawy gwintu nie jest konieczne zdjęcie głowicy – the shavings from the tap are minimal due to its design (small filings from aluminum heads are blown out by turning the starter or burned during engine operation and pose practically no threat).

The only drawback of this method is the high cost of the tooling, practically unprofitable with a one-time repair.

Therefore, when deciding on the given method of repair, let's find out, there is no repair shop nearby, who uses such inserts.

Repair in a specialist workshop will be reliable, fast and relatively inexpensive.

Finally, some practical considerations. To avoid the need to repair the thread of the spark plug socket in the head:

– nie wkręcajmy zimnej śwrecy do nagrzanej głowicy, due to shrinkage of the head material, it may turn out, that the candle was tightened more than we intended to do

– nie wkręcajmy świec z długim gwintem w gniazda z krótkim gwintem z uwagi na to, that the protruding part of the spark plug thread will be covered with carbon deposits from the combustion chamber and that when unscrewing the plug, the thread in the head may be damaged

– świecę należy wkręcać w pierwszej fazie ręką lub kluczem bez przetyczki; if there is considerable resistance to screwing, it is necessary to check, what is the reason for this.

I have been using Heli-Coil inserts in my workshop for many years and I had no complaints about it, and a candle was presented to me as a curiosity, which is screwed crookedly into the socket with the Heli-Coil insert. A second thread was cut on the candle, while the liner remained undamaged. Although the material of the candle body is not too hard, however, this fact proves the high quality of the insoles, and in practice you can say, that it is an "eternal thread."”.